Category

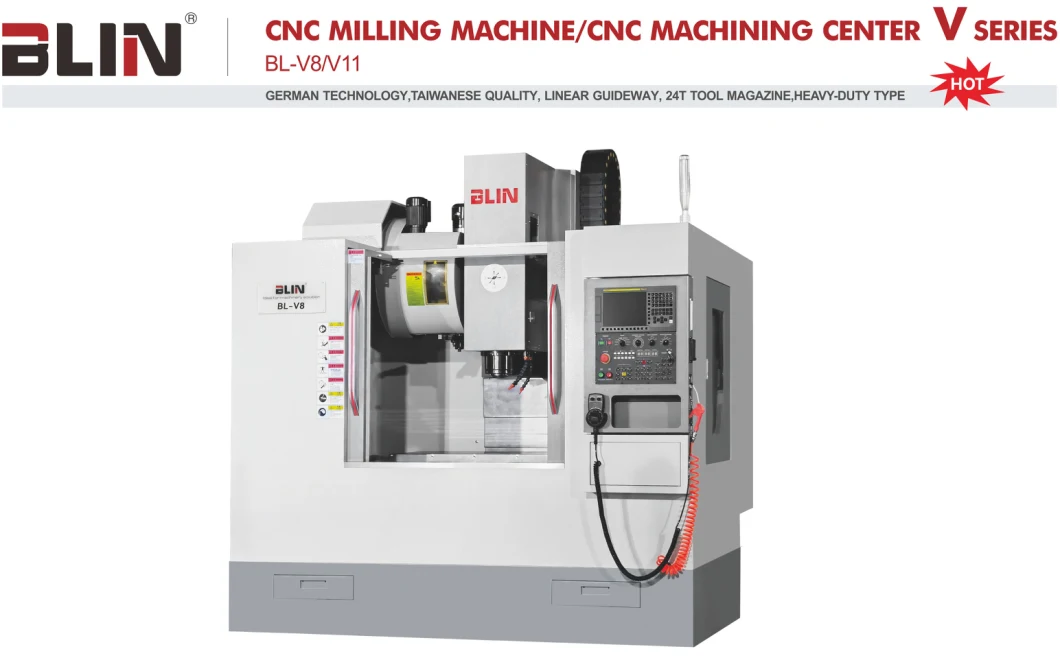

High Quality CNC Machining Center CNC Milling Machine with German Technology (BL-V8/V11)

CNC Machining Center/CNC Milling Machine/Milling Machine(BL-V8/V11) -3 axes ROLLER type linear guideway, Heavy-duty type

Basic Info

| Model NO. | BL-V8/V11 |

| After-sales Service | One Year |

| Warranty | One Year |

| Type | Worktable Milling Machine |

| Object | Metal |

| Structure | Bed type |

| Milling Cutter Type | Vertical Milling Cutter |

| Milling Cutter Structure | Integral |

| Controlling Mode | CNC |

| Automatic Grade | Semiautomatic |

| Precision | High Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Table Size | 1000×550mm;1200(1300)×600mm |

| X/Y/Z Axes Travel | 800/550/550, 1100/600/600mm |

| Table Max. Loading | 700/900kg |

| Spindle Nose | Bt40 |

| Spindle Motor | 7.5/11;11/15kw |

| Spindle Speed | 8000/10000/12000rpm |

| Tool Magazine | 24t Arm Type |

| Positioning Precision | ±0.005mm |

| Repeatable Positioning Precision | ±0.003mm |

| Transport Package | Woode Case |

| Specification | 800/550/550mm; 1100/600/600mm |

| Trademark | BLIN |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 480 Units/Year |

Product Description

CNC Machining Center/CNC Milling Machine/Milling Machine(BL-V8/V11) -3 axes ROLLER type linear guideway, Heavy-duty type,suitable for heavy-duty cutting - Whole production process accord to TAIWAN standard - Most parts adopt GERMAN/JAPAN/TAIWAN brand - High speed, high precision, long using lifespan - Adopt HT300 high class cast iron,after aging treatment and FEA analysis - Bridge shape column, high rigidity, high stability - Use 24T Arm type ATC, adopt CAM driving, fast and stable tool changing, tool selection for bi-way as random. - 3 axes use C3 class precision ball screw, match up nut preloading and ball screw pre-stretching, pre-eliminate backlash and temperature rising, ensure stable positioning and repeatable positioning precisionDetails:

| Item | Specification | Unit | BL-V8 | BL-V11 |

| Worktable | Table size | mm | 1000×550 | 1200(1300*)×600 |

| T slot(NO./width/gap) | mm | 5/18/90 | 5/18/100 | |

| Table max. loading | kg | 700 | 900 | |

| Travel | X/Y/Z axes travel | mm | 800/550/550 | 1100/600/600 |

| Spindle | Distance from spindle nose to table surface | mm | 120~670 | 120~720 |

| Distance from spindle center to column face | mm | 600 | 650 | |

| Spindle type | / | BT40 | ||

| Spindle motor | kw | 7.5/11; 11/15(opt.) | 11/15 | |

| Spindle speed | rpm | 8000(option:10000 belt-drive;12000/15000 direct-drive) | ||

| Feeding axes | X/Y/Z axes linear guideway width | mm | 35/45/45(ROLLER type)Z axes 6pcs slide blocks | 45/45/45(ROLLER type)X,Z axes 6pcs slide blocks |

| X/Y/Z axes max. rapid moving speed | m/min | 48/48/48 | 36/36/36 | |

| X/Y/Z axes ball screw dia./pitch | mm | 40/16 | 40/12 | |

| X/Y/Z axes motor torque | Nm | 22/22/22 | ||

| Precision | Positioning precision | mm | ±0.005 | |

| Repeatable positioning precision | mm | ±0.003 | ||

| Tool magazine | Tool magazine type | / | 24T Arm type | |

| Max. tool weight | kg | 7 | 8 | |

| Max. tool length | mm | 280 | ||

| Max. tool dia.(fully loaded) | mm | 80 | ||

| Max. tool dia.(no adjacent) | mm | 110 | ||

| Tool changing time | / | Tool to tool: 1.8s | Tool to tool: 2s | |

| Others | Overall Size | mm | 2500×2200×2500 | 2900×2300×2600 |

| Weight | kg | 5500 | 7200 | |

Main parts brand:

| Item | Brand |

| Spindle bearing | JAPAN-NSK/GERMANY-FAG |

| Ball screw bearing | JAPAN-NACHI/GERMANY-FAG |

| Linear guideway | TAIWAN-HIWIN,PMI/GERMANY-REXROTH |

| Ball screw | TAIWAN-HIWIN/PMI |

| Shaft coupler | JAPAN-NBK/MIKI PULLEY |

| Spindle | TAIWAN-KENTURN/VYU CHENG |

| Tool magazine | TAIWAN-DEX |

| Booster cylinder | TAIWAN-CHEN SOUND |

| Pnuematic parts | TAIWAN-MINDMAN |

| Lubrication pump | JAPAN-LUBE |

| Electric parts | FRANCE-SCHNEIDER |

Standard configuration: -FANUC 0i MF CNC Controller-24T Arm type tool magazine Optional configuration: -SIEMENS 828D CNC controller-Chip conveyor-Coolant through spindle-Tool setting probe -4th axes-5th axes

Other models choice:All our machines range:

About us: